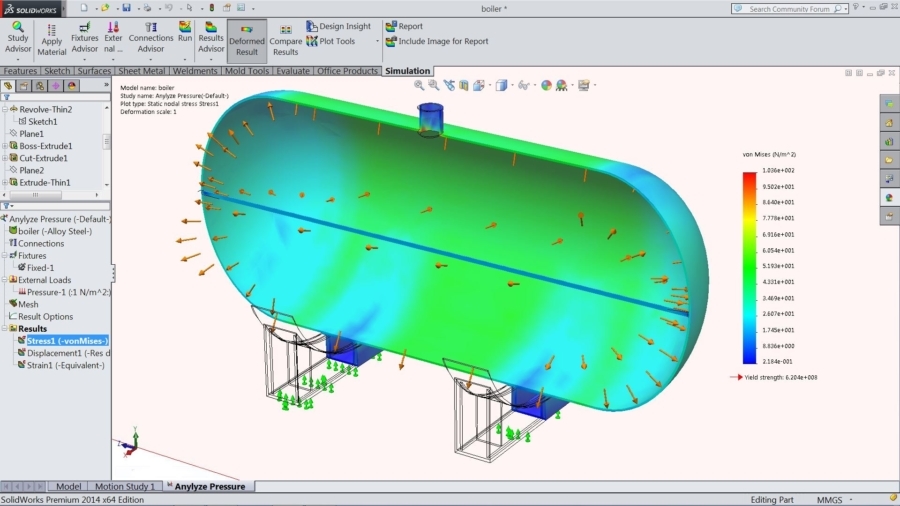

Process plant is often exposed to corrosive environments and/or elevated temperatures. Under these conditions, the material used in this equipment can degrade or age with time in service. Pressure vessels and piping systems become older, the plant operator must decide if they can continue to operate safely and reliably to avoid injuries to personnel and the public, environmental damage, and unexpected shutdowns.

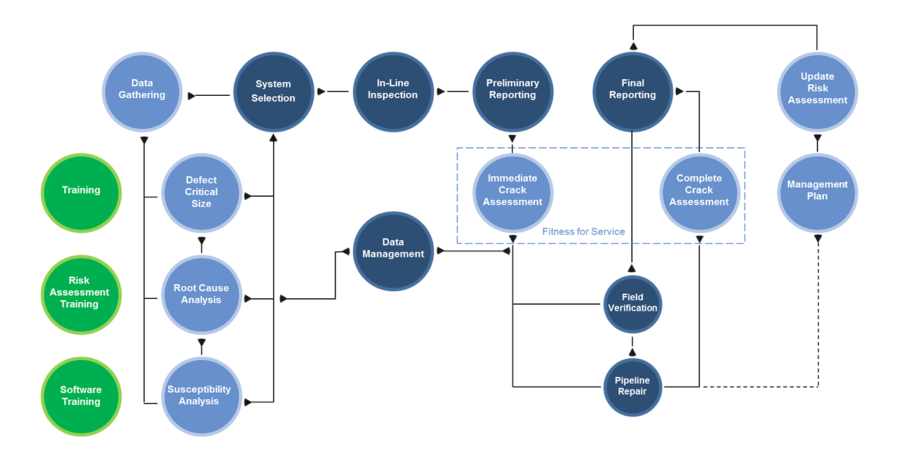

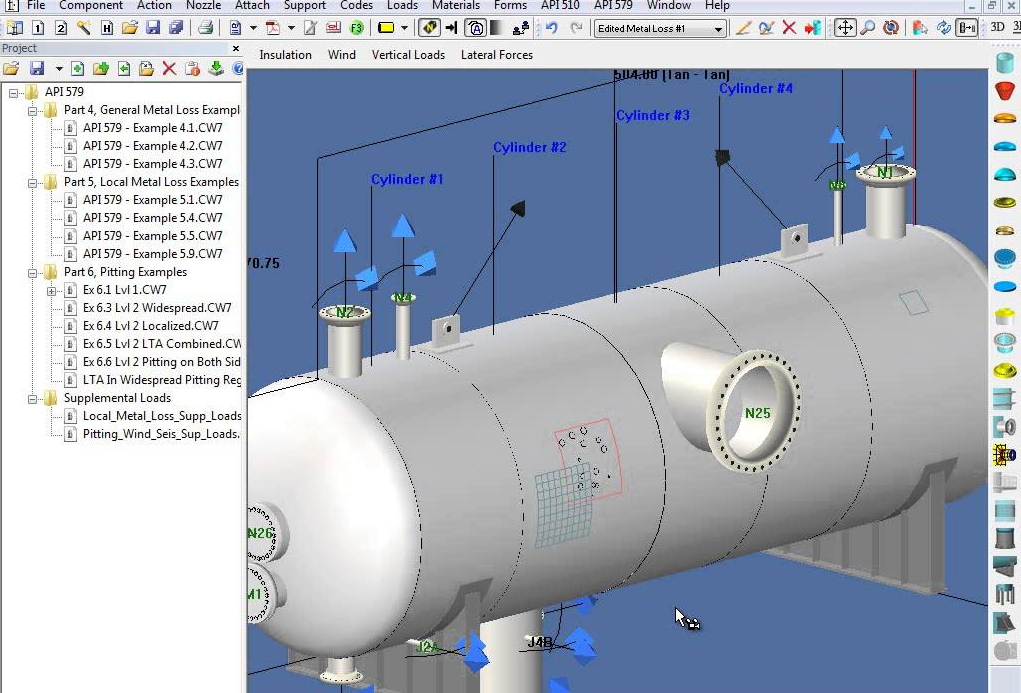

Common reasons for assessing the fitness for service of equipment include the discovery of a flaw such as a locally thin area (LTA) or crack, failure to meet current design standards, and plans for operating under more severe conditions than originally expected

SV Engineering provides specialists and engineering support in all areas of Asset Integrity Management, including design, process safety, mechanical integrity, inspection and maintenance, operational and process support, corrosion, metallurgy, and risk analysis.

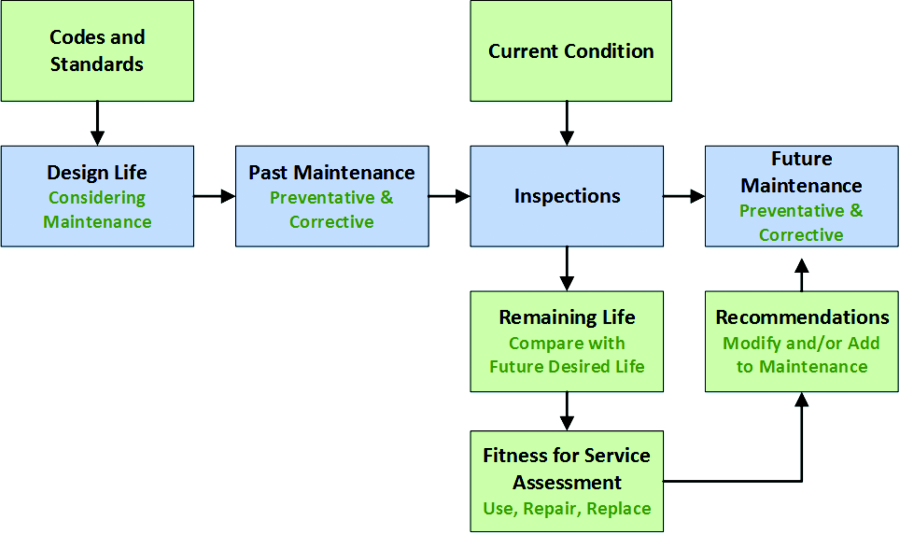

The integrity study of the current state of an installation on service will be based to:

- Prepare of Quality Control Plan with all related documents (ITP, inspection Procedures, DWG, method statement…)

- Inspection execution as per International standards (API 510, API 570 API 653…)

- FFS Analysis in accordance with API 579 of detected anomalies.

- Recommendation of necessary repair or alteration.

- Implementation of an RBI System.